|

Slides 114 - 118 |

|

|

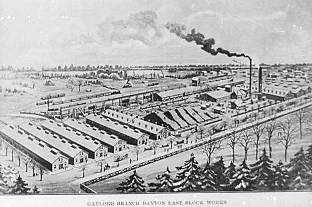

1. When

the white pine was no longer abundant, there was hardwood to be

harvested. In 1894, the Dayton Last Block Company from |

|

|

|

2. The

hardwoods - maple, beech, and birch - were logged and brought to the

plant which was located on |

|

3. These logs were cut into blocks, kiln dried, roughly shaped into lasts, and then shipped by rail to shoe manufactures all over the country. It could be said that Gaylord was the center of supply for this particular industry. |

|

|

|

4. For 36 years, the factory played an important role in the local economy. It was a big operation and employed a large number of people. |

|

5. Frank Shipp - a prominent Gaylord citizen - was the manager or superintendent of the plant. Old timers often tell about how they burned wagon loads of defective last blocks in their kitchen stoves. The plant ceased operations in 1930. |

|